Electroless Nickel

Electroless Nickel plating is a non-electrolytic, auto-catalytic, immersion chemical plating method of depositing a Nickel Phosphorous alloy for engineering applications, deposits from 5 to 75 micron thickness can be applied to most metallic substrate materials, for a wide range of applications.

Electroless Nickel is classed as a “COLD” process, with application process temperatures in the order of 85 – 95°C, ensuring no detrimental effects to the physical and mechanical properties of the base materials. Electroless Nickel for engineering applications is covered by ASTM B656-86 and B733-86.

Localised deposits can be produced by masking areas that do not require plating.

Electroless Nickel Plating (AMS 2404E)

Maximum Thickness: 75 um Maximum Plating Rate: 12.5um/hr

Maximum Length – 3600mm Maximum Diameter or Width – 850mm

Maximum Weight – 5 tonne Floor to Hook Height 3T crane: 5.20m

Maximum Length on Flight Bar A10 and A11: 1600mm

Highlights

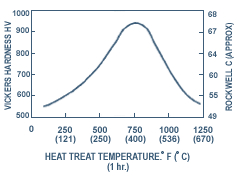

High Hardness

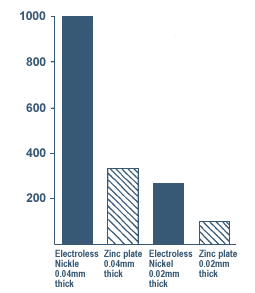

Excellent Corrosion Resistance

1,000 Hours Salt Spray Test

5-75 Microns Thickness

Good Wear Resistance

Low Friction

For Ferrous and Non-Ferrous Metals

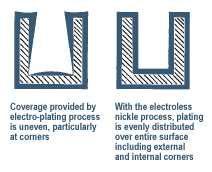

Uniform Coating Thickness

Up To 67 HRc Hardness

“Cold” Process

Corrosion Resistance

High Hardness

Low Coefficient of Friction

Typical Applications for Electroless Nickel

Hydraulic and Pneumatic Components

Rods, Pistons, Cylinders

Pumping Equipment

Housings, Rotors, Impellors,Valves, Fittings, Shafts

Valve Components

Balls, Gates & Discs, Plugs,Butterflies and Shafts

Mechanical Components Oil and Gas Equipment

Packers, Rods, Fire Tubes and Barrels

Plastic Moulds, Dies, Screws and Fittings Food Equipment

Gang Knives, Slicing Blades, Bowls, Mixing Blades, Presses, Timing Screws, Hooks, Conveyor Chain

Automotive Components

Diff Pins, Rocker Arms, Steering Unit Comp., Shocker Rods, Brake Pistons, Fuel Injection Comp., Trans. Thrust Washers

Chemical Equipment

Heat Exchangers, Filter Units, Mixing Equipment, Tubing

Scientific Equipment Medical Components Foundry Patterns, Paper and Pulp, Textile

Equipment and Aerospace Components.

Hours to failure

Uniform Coating Thickness

Relationship with Heat Treat Temperatre for Nickel Phosphorus Coatings