Hardchrome Engineering has a broad range of processes and technologies which are constantly being improved and expanded. Technologies include:

In its most simple form Heat Treatment is a process of applying heat at a known temperature over a known period of time to change the physical properties or microstructure of a material

Laser cladding is the process of adding a pure metal or an alloy in its powder form to a new or damaged component for wear, corrosion, abrasion protection or for salvaging worn parts

Our large Fabrication and Machine shop in Yallourn, LaTrobe Valley, Victoria with wide bays and high roof line lends itself very well to larger project and construction works – all under a single roof

Hard Chrome plating is an electrolytic method of depositing Chrome for engineering applications, from a Chromic acid solution.

Tungsten Carbide Wear Plate developed and manufactured in Australia by Hardchrome Engineering for the most extreme, aggressive abrasive or erosive environments

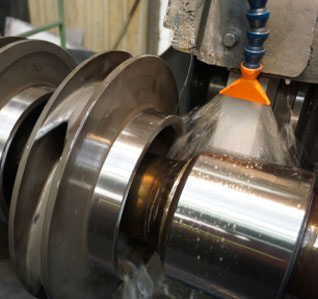

Our machine shop in Yallourn was originally constructed and fitted out with the sole purpose of offering engineering support to Yallourn Power Station.

Hydraulics and associated components are an essential and integral part of industry. Over the last 40 years, Hardchrome Engineering (HCE) has gained extensive experience in the repair, refurbishment and reclamation of hydraulic components.

Electroless Nickel plating is a non-electrolytic, auto-catalytic, immersion chemical plating method of depositing a Nickel Phosphorous alloy for engineering applications

Working within tight dimensional tolerances associated with our industry is paramount to our success. Quality is a key essential and justifies the full-time role of an experienced Quality Manager to overview our systems.